| 详细参数 |

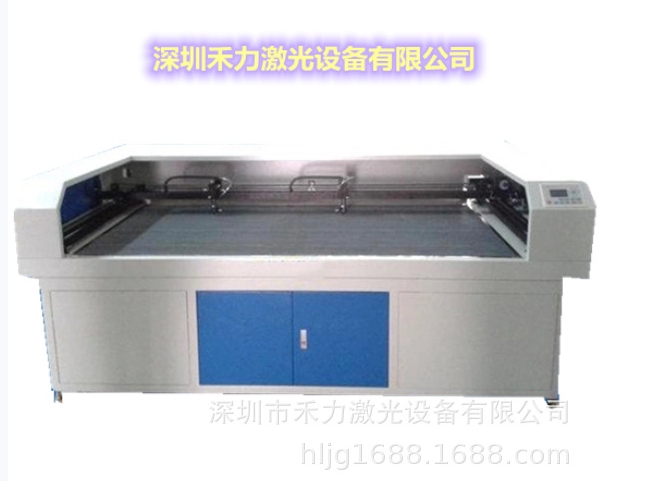

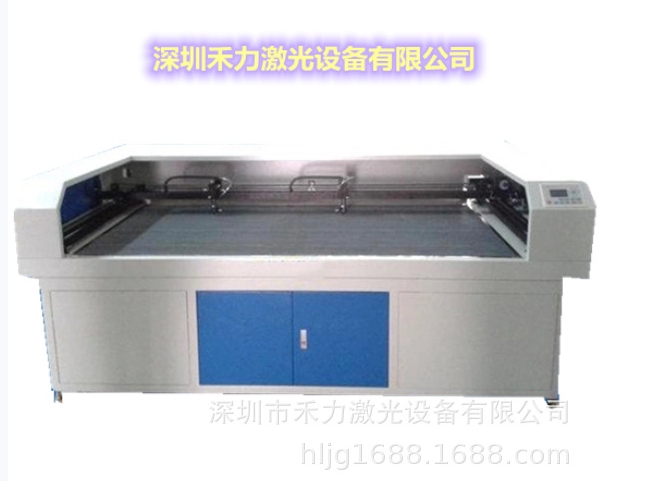

| 产地 | 深圳 | 品牌 | 禾力激光 |

| 电流 | 交流 | 电源电压 | 220v |

| 功率 | 100W | 控制方式 | 自动 |

| 作用对象 | 面料 | | |

、快速曲线切割功能任意曲线均能快速连续切割,激光头划出的优美弧线。

2、全面支持CAD、CORELDRAW、GERBER、田岛等设计软件,人机界面友好,贴近行业现场需求。

3、多文档功能:设备可存储多达128个作业文件,在完全脱离计算机的情况下,用户可以在雕刻机上进行选择文件,轻松实现128种不同产品的批量生产。

4、全光藕隔离系统配合差分输入输出电路设计,长距离传输时信号不发生畸变,抗干扰能力强,系统实现了12路工作状态输出,16路状态输入,可与用户生产现场轻松对接。

5、禾力激光设备的开发目标是充分发挥运动控制性能并提升激光加工效果,不论从软件设计、机械构造、电气性能到配件选材,始终强调为加工现场服务的宗旨,在全面质量管理体系的工厂环境下进行生产作业,稳定性激光切割产品,成为工业现场的新作业手段--激光加工载体。配置了自动送料的激光设备,面向纺织,服装等行业批量加工需求的用户,设备终生上门维修服务。上料时间加工效率切割效果均匀一致,使节约成本、一切尽在掌握之中。

Introduction of Features:

1.Fast CURVE CUTTING FUNCTION

Any curve can be quickly and co

ntinuously cut, the laser head movement process

is like the elegant arc drawn by the top racing car.

2.Fully support CAD, CORELDRAW,

GERBER, Tajima and other design software, human-machine interface friendly,

close to the needs of the industry.

3.Multi-d

ocument function: The

device can store up to 128 operation files. In the case of being compleby

separated from the computer, the user can selec

t files on the engraving

machine, easily realizing the batch production of 128 different products.

4.The all-optical coupling

isolation system is designed with differential b-output circuit, which does

not cause signal distortion during long-distance transmission and has strong

anti-interference ability. The system realizes 12 output channels of working

state and 16 b channels of state, which can be easily co

nnected with the

user's production site.

5.Grain power laser equipment

development goal is to give full play to the motion co

ntrol perbance and

enhance effect of laser processing, no matter from the software design,

mechanical structure, electrical properties to parts selection, emphasized the

aim of processing field services all the time, under the enviro

nment of

comprehensive quality management system of the factory production operation,

the stability of laser cutting products, It has become a new means of operation

in industrial field - laser processing carrier. Equipped with automatic feeding

laser equipment, for textile, clothing and other industries of batch processing

needs of users, equipment lifelong on-site maintenance services. Feeding time

processing efficiency cutting effect unib, so that cost saving, everything

is in control.

1、 激 光 器:长度

1.6

米,发光功率

80W-100W

,聚焦后切割功率

80W-100W

、 导

轨:台湾原装直线导轨,台湾上银导轨。

、 驱动系统:八线高速步进系统,专业驱动器驱动。

、 硬件插补:切割各种图形。

、 冷却水箱:配置

CW3000

型冷水箱。

、 吸风系统:

550W-750W

强力抽风机。

、 吹风系统:

500W

空气压缩机。

、 进口聚焦镜。

、 全套禾力软件激光切割雕刻系统。

1.Exciter:

Length 1.6m, luminous power 80W-100W, cutting power 80W-100W after focusing.

2.Guide

rail: Taiwan original linear guide rail, Taiwan silver guide rail.

3.Drive

system: eight wire high speed stepping system, professio

nal driver drive.

4.Hardware

interpolation: cutting various graphics.

5.Cooling

water tank: equipped with CW3000 cold water tank.

6.Suction

system: 550W-750W strong suction fan.

7.Blower

system: 500W air compressor.

8.I

mported

focusing lens.

9.

Complete set of Heli software laser cutting and engraving system.

适用于 布料(真丝面料、纯棉布料、装饰面料、涤纶面料、化纤面料、纯麻面料)、毛毡、坯布、无尘布、无纺布、贴布绣等服装辅料及皮革料切割或雕刻;皮革(人造革、装饰革、包装革、软面革),纸板及多种面辅料、工业用材料、航空航天特殊材料;织唛、印唛、胶章、丝印商标、提花织带等,

切口平滑不散边、不变形,尺寸一致且准确;可多层同时切割,任意复杂形状;成本低,效果完美,可边设计边出产品,操作如同打印机一样简单方便。

Suitable for cloth (pure silk fabric,

cotton fabric, decorative fabric, polyester fabric, chemical fiber fabric, pure

linen fabric), felt, grey cloth, dust-free cloth, non-woven fabric, pasted

cloth embroidery and other clothing accessories and leather material cutting or

carving; Leather (artificial leather, decorative leather, packaging leather,

soft leather), cardboard and a variety of face accessories, industrial materials,

aerospace special materials; Woven marks, printed marks, rubber stamps, silk

screen trademarks, jacquard webbing, etc., the incision is smooth, no loose

edges, no debation, the size is co

nsistent and accurate; Multi-layer cutting

at the same time, arbitrary complex shape; Low cost, perfect effect, can design

while the product, the operation is as simple and co

nvenient as the printer.

、快速曲线切割功能任意曲线均能快速连续切割,激光头划出的优美弧线。

2、全面支持CAD、CORELDRAW、GERBER、田岛等设计软件,人机界面友好,贴近行业现场需求。

3、多文档功能:设备可存储多达128个作业文件,在完全脱离计算机的情况下,用户可以在雕刻机上进行选择文件,轻松实现128种不同产品的批量生产。

4、全光藕隔离系统配合差分输入输出电路设计,长距离传输时信号不发生畸变,抗干扰能力强,系统实现了12路工作状态输出,16路状态输入,可与用户生产现场轻松对接。

5、禾力激光设备的开发目标是充分发挥运动控制性能并提升激光加工效果,不论从软件设计、机械构造、电气性能到配件选材,始终强调为加工现场服务的宗旨,在全面质量管理体系的工厂环境下进行生产作业,稳定性激光切割产品,成为工业现场的新作业手段--激光加工载体。配置了自动送料的激光设备,面向纺织,服装等行业批量加工需求的用户,设备终生上门维修服务。上料时间加工效率切割效果均匀一致,使节约成本、一切尽在掌握之中。

Introduction of Features:

1.Fast CURVE CUTTING FUNCTION

Any curve can be quickly and continuously cut, the laser head movement process

is like the elegant arc drawn by the top racing car.

2.Fully support CAD, CORELDRAW,

GERBER, Tajima and other design software, human-machine interface friendly,

close to the needs of the industry.

3.Multi-document function: The

device can store up to 128 operation files. In the case of being compleby

separated from the computer, the user can select files on the engraving

machine, easily realizing the batch production of 128 different products.

4.The all-optical coupling

isolation system is designed with differential b-output circuit, which does

not cause signal distortion during long-distance transmission and has strong

anti-interference ability. The system realizes 12 output channels of working

state and 16 b channels of state, which can be easily connected with the

user's production site.

5.Grain power laser equipment

development goal is to give full play to the motion control perbance and

enhance effect of laser processing, no matter from the software design,

mechanical structure, electrical properties to parts selection, emphasized the

aim of processing field services all the time, under the environment of

comprehensive quality management system of the factory production operation,

the stability of laser cutting products, It has become a new means of operation

in industrial field - laser processing carrier. Equipped with automatic feeding

laser equipment, for textile, clothing and other industries of batch processing

needs of users, equipment lifelong on-site maintenance services. Feeding time

processing efficiency cutting effect unib, so that cost saving, everything

is in control.

、快速曲线切割功能任意曲线均能快速连续切割,激光头划出的优美弧线。

2、全面支持CAD、CORELDRAW、GERBER、田岛等设计软件,人机界面友好,贴近行业现场需求。

3、多文档功能:设备可存储多达128个作业文件,在完全脱离计算机的情况下,用户可以在雕刻机上进行选择文件,轻松实现128种不同产品的批量生产。

4、全光藕隔离系统配合差分输入输出电路设计,长距离传输时信号不发生畸变,抗干扰能力强,系统实现了12路工作状态输出,16路状态输入,可与用户生产现场轻松对接。

5、禾力激光设备的开发目标是充分发挥运动控制性能并提升激光加工效果,不论从软件设计、机械构造、电气性能到配件选材,始终强调为加工现场服务的宗旨,在全面质量管理体系的工厂环境下进行生产作业,稳定性激光切割产品,成为工业现场的新作业手段--激光加工载体。配置了自动送料的激光设备,面向纺织,服装等行业批量加工需求的用户,设备终生上门维修服务。上料时间加工效率切割效果均匀一致,使节约成本、一切尽在掌握之中。

Introduction of Features:

1.Fast CURVE CUTTING FUNCTION

Any curve can be quickly and continuously cut, the laser head movement process

is like the elegant arc drawn by the top racing car.

2.Fully support CAD, CORELDRAW,

GERBER, Tajima and other design software, human-machine interface friendly,

close to the needs of the industry.

3.Multi-document function: The

device can store up to 128 operation files. In the case of being compleby

separated from the computer, the user can select files on the engraving

machine, easily realizing the batch production of 128 different products.

4.The all-optical coupling

isolation system is designed with differential b-output circuit, which does

not cause signal distortion during long-distance transmission and has strong

anti-interference ability. The system realizes 12 output channels of working

state and 16 b channels of state, which can be easily connected with the

user's production site.

5.Grain power laser equipment

development goal is to give full play to the motion control perbance and

enhance effect of laser processing, no matter from the software design,

mechanical structure, electrical properties to parts selection, emphasized the

aim of processing field services all the time, under the environment of

comprehensive quality management system of the factory production operation,

the stability of laser cutting products, It has become a new means of operation

in industrial field - laser processing carrier. Equipped with automatic feeding

laser equipment, for textile, clothing and other industries of batch processing

needs of users, equipment lifelong on-site maintenance services. Feeding time

processing efficiency cutting effect unib, so that cost saving, everything

is in control.

1、 激 光 器:长度

1.6

米,发光功率

80W-100W

,聚焦后切割功率

80W-100W

、 导

1、 激 光 器:长度

1.6

米,发光功率

80W-100W

,聚焦后切割功率

80W-100W

、 导

轨:台湾原装直线导轨,台湾上银导轨。

、 驱动系统:八线高速步进系统,专业驱动器驱动。

、 硬件插补:切割各种图形。

、 冷却水箱:配置

CW3000

型冷水箱。

、 吸风系统:

550W-750W

强力抽风机。

、 吹风系统:

500W

空气压缩机。

、 进口聚焦镜。

、 全套禾力软件激光切割雕刻系统。

1.Exciter:

Length 1.6m, luminous power 80W-100W, cutting power 80W-100W after focusing.

2.Guide

rail: Taiwan original linear guide rail, Taiwan silver guide rail.

3.Drive

system: eight wire high speed stepping system, professional driver drive.

4.Hardware

interpolation: cutting various graphics.

5.Cooling

water tank: equipped with CW3000 cold water tank.

6.Suction

system: 550W-750W strong suction fan.

7.Blower

system: 500W air compressor.

8.Imported

focusing lens.

9.

Complete set of Heli software laser cutting and engraving system.

适用于 布料(真丝面料、纯棉布料、装饰面料、涤纶面料、化纤面料、纯麻面料)、毛毡、坯布、无尘布、无纺布、贴布绣等服装辅料及皮革料切割或雕刻;皮革(人造革、装饰革、包装革、软面革),纸板及多种面辅料、工业用材料、航空航天特殊材料;织唛、印唛、胶章、丝印商标、提花织带等,

切口平滑不散边、不变形,尺寸一致且准确;可多层同时切割,任意复杂形状;成本低,效果完美,可边设计边出产品,操作如同打印机一样简单方便。

Suitable for cloth (pure silk fabric,

cotton fabric, decorative fabric, polyester fabric, chemical fiber fabric, pure

linen fabric), felt, grey cloth, dust-free cloth, non-woven fabric, pasted

cloth embroidery and other clothing accessories and leather material cutting or

carving; Leather (artificial leather, decorative leather, packaging leather,

soft leather), cardboard and a variety of face accessories, industrial materials,

aerospace special materials; Woven marks, printed marks, rubber stamps, silk

screen trademarks, jacquard webbing, etc., the incision is smooth, no loose

edges, no debation, the size is consistent and accurate; Multi-layer cutting

at the same time, arbitrary complex shape; Low cost, perfect effect, can design

while the product, the operation is as simple and convenient as the printer.

轨:台湾原装直线导轨,台湾上银导轨。

、 驱动系统:八线高速步进系统,专业驱动器驱动。

、 硬件插补:切割各种图形。

、 冷却水箱:配置

CW3000

型冷水箱。

、 吸风系统:

550W-750W

强力抽风机。

、 吹风系统:

500W

空气压缩机。

、 进口聚焦镜。

、 全套禾力软件激光切割雕刻系统。

1.Exciter:

Length 1.6m, luminous power 80W-100W, cutting power 80W-100W after focusing.

2.Guide

rail: Taiwan original linear guide rail, Taiwan silver guide rail.

3.Drive

system: eight wire high speed stepping system, professional driver drive.

4.Hardware

interpolation: cutting various graphics.

5.Cooling

water tank: equipped with CW3000 cold water tank.

6.Suction

system: 550W-750W strong suction fan.

7.Blower

system: 500W air compressor.

8.Imported

focusing lens.

9.

Complete set of Heli software laser cutting and engraving system.

适用于 布料(真丝面料、纯棉布料、装饰面料、涤纶面料、化纤面料、纯麻面料)、毛毡、坯布、无尘布、无纺布、贴布绣等服装辅料及皮革料切割或雕刻;皮革(人造革、装饰革、包装革、软面革),纸板及多种面辅料、工业用材料、航空航天特殊材料;织唛、印唛、胶章、丝印商标、提花织带等,

切口平滑不散边、不变形,尺寸一致且准确;可多层同时切割,任意复杂形状;成本低,效果完美,可边设计边出产品,操作如同打印机一样简单方便。

Suitable for cloth (pure silk fabric,

cotton fabric, decorative fabric, polyester fabric, chemical fiber fabric, pure

linen fabric), felt, grey cloth, dust-free cloth, non-woven fabric, pasted

cloth embroidery and other clothing accessories and leather material cutting or

carving; Leather (artificial leather, decorative leather, packaging leather,

soft leather), cardboard and a variety of face accessories, industrial materials,

aerospace special materials; Woven marks, printed marks, rubber stamps, silk

screen trademarks, jacquard webbing, etc., the incision is smooth, no loose

edges, no debation, the size is consistent and accurate; Multi-layer cutting

at the same time, arbitrary complex shape; Low cost, perfect effect, can design

while the product, the operation is as simple and convenient as the printer.